The industrial workplace is very dynamic due to the range of operations that take place in it. Regardless of whether you deal with the manufacturing, storage or transport of goods, the truth is that the safety and efficiency of the place, as well as those of the employees, depend on adequate equipment.

Why Is Investing in Equipment Important?

As various operations can happen under the same roof, you require a diverse array of essential workplace equipment to keep up with the continuous evolution of the industrial work scene. But that’s certainly not the only reason why it’s imperative to invest in the right gear.

Consider the investment as a crucial step for maintaining competitiveness in the already busy and modern marketplace for the following range of benefits it can offer:

The Increase in Productivity

You may not think of material handling, inventory management, cleaning, pallet racking, shelving and storage solutions, or conveyor systems as crucial, but think of the reduction in productivity when working without them. The reason this type of advanced workplace equipment comes in handy has to do with what it’s designed for—speeding up the whole process while cutting down on the need for manual labour.

The outcome is a boost in the quality of work overall due to fewer instances of errors, defects, and damages. Also important to mention is that you can expect to benefit from higher output and faster turnaround times, as well as overall higher standards for the quality of services you provide.

The adequate machinery and tools make for precise and accurate results with consistency as well. So, all things considered, you can expect to keep customers coming back for more of what it is you offer, which leads to a boost in the reputation and, respectively, the income too.

The Cost Savings

Think of it this way: the end result (i.e., cost savings) outweighs the initial costs of the investment. What you invest now in industrial supplies shouldn’t be thought of as a cumbersome step or a setback, but rather as a wise and strategic move that will keep paying you back in the upcoming business years.

When you have employees who are more productive without putting in more physical effort and you have a higher quality of work as a result, you can be happy with less of a risk of compensation claims, sick leaves, defects, damages, and costly repairs. Not to mention, acquiring equipment that meets, or even exceeds, industry safety regulations and standards means you also protect the business and reputation from fines or potential legal issues.

Lastly, replacing outdated machinery and tools with top-notch varieties that are made according to the latest standards and implementing the latest technology means you set yourself up for success as there are fewer risks of maintenance and repair costs ahead. A smart move with a guaranteed positive impact!

The Employee Satisfaction

If you want to have a company where there’s a pleasant work atmosphere and work ethic, get the needed workplace safety gear and efficiency (e.g., streamlining, material handling, automated storage, RFID) equipment and see employee satisfaction go up.

Having access to up-to-date machinery and tools that are according to the protocol enhances their ability to perform the needed tasks with the utmost efficiency, which significantly leads to an increase in motivation, a feeling of value, and being part of the team. Don’t be surprised if this investment results in a higher employee retention rate too.

Types of Essential Industrial Equipment

Keeping the workplace safe, efficient, and clean is of utmost importance, as already mentioned, which is where the workplace equipment proves to be of help. With so many options for machinery and tools available nowadays, it can be confusing as to what’s essential.

While it mainly comes down to what it is your company deals with—the line of work, the services, the tasks, and the supplies specifically—there’s some basic gear that’s usually associated with this work environment.

Material Handling

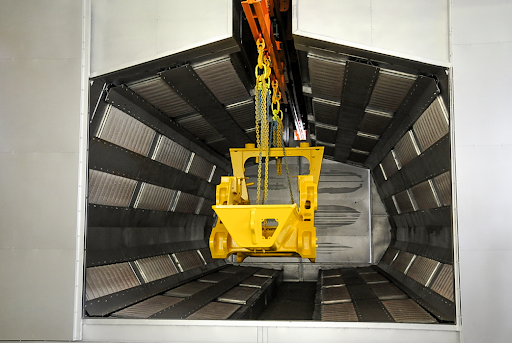

Moving, lifting, storing, and transporting goods is a process that requires a great deal of force and effort, putting employees in danger of sustaining injuries as well as putting goods at risk of sustaining damages. To ensure a smooth process with minimal danger and risk, you should focus on utilising cutting-edge conveyors, pallet jacks, trolleys, pallet racking systems, mezzanine systems, shelving units, and machinery like forklifts and cranes.

What are the benefits of handling equipment? Well, you can easily and seamlessly keep an eye on the stock, no matter how great it may be in quantity and size, thus keeping the whole workspace organised and efficient. No longer would employees have to spend considerable time trying to locate the needed goods or store them in their designated area. Reducing the operational costs while optimising the overall flow of the facility is a given!

Safety Equipment

Every work environment poses its own safety risks that should be dealt with as best as possible with adequate equipment, and what that equipment is going to be depends on the type of business you have. For some, workplace safety clothing like PPE is going to be enough; for others who work with material handling equipment and machinery, there’s also the need to include proper signage and alarms to ensure no one gets involved in accidents and injuries. Ramps, matting, and full-body safety harnesses are other pieces of safety gear that could come in handy.

Industrial Storage

A high-density storage environment could do with automated retrieval systems (AS/RS) that reduce the need for manually storing, organising, and retrieving the goods, thus reducing the time and effort it takes to complete such tasks. When you count on automated machinery and vehicles, there’s also a reduction in the risk of damages and costly replacements of the stock.

Cleaning Supplies

Cleaning and proper maintenance of the hygiene of the workplace by employing adequate waste management practises are both crucial factors that are part of staying compliant with the safety regulations. This makes purchasing suitable cleaning supplies a necessity, much like the rest of the equipment already covered in the text.

From simple sweepers and vacuums to industrial floor scrubbers, pressure washers, trash compactors and bins, plus cleaning chemicals and organising carts and trolleys, there’s the ideal supply for your line of business. Estimate the risks, do a checklist of the crucial cleaning supplies, and you can provide a clean and optimal environment for everyone.