Do you need to repair a concrete surface? Even though it may seem like a complex project, it can be done in one simple step using epoxy glue. However, to get a good result, you must know how to pick and use it properly. Here’s everything you need to know about using this unique adhesive for concrete.

What Is Epoxy Glue?

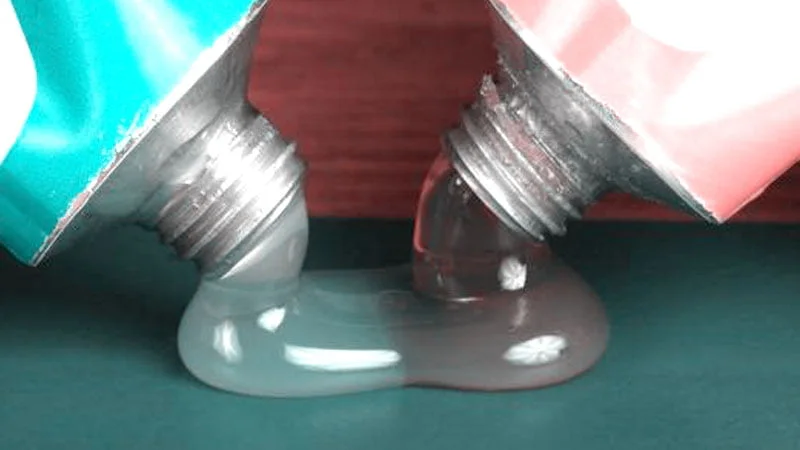

Simply, it’s a blend of epoxy resin and a hardener. When equal parts of these substances are combined, they react to form a strong, stiff and resilient bond that you can use to fill, bind, reconstruct, and repair concrete surfaces.

Since being introduced in the 1940s, epoxy resin has been used in a wide range of applications. It’s considered one of the most versatile materials today due to its exceptional adhesion, high mechanical strength, heat and water resistance, short cure times, and low shrinkage rates. It also works well as a protective coating or filler in various goods, from electrical component adhesives to concrete floor sealers.

As epoxy is a thermoset polymer, so it can create a variety of fillers, adhesives, and protective coatings. Although it’s as viscous as a liquid, when combined with hardeners and additives, it cures and hardens swiftly. Depending on the hardeners and additives employed, pot life and curing times can be altered for the particular application.

After hardening, it shows great strength, dimensional stability, and chemical resistance. Additionally, the commercially available epoxy glue adheres readily to a variety of materials, including concrete, glass, metal, stone, and wood.

You consider the environment the glue will interact with to choose which product to get. Will the weather be a factor? Will it be regularly exposed to moisture or water? Will it need to be machined or drilled after it has dried? What range of temperatures will it experience? Check the manufacturer’s information to be sure the two-part concrete epoxy you choose can withstand those circumstances.

You must understand that epoxy resin glue and epoxy paint are not the same. Although paints are often more durable than normal paint, they fall far short of the longevity of adhesive coatings.

Paints typically have one layer, whereas concrete coatings often have three layers, comprising the colour, the base, and the topcoat, with a combined thickness that ranges from 1mm to 5mm.

What Are the Benefits of This Adhesive?

You Can Use It on Any Concrete Surface

On driveways, indoor concrete floors, and other surfaces, this glue can be used anywhere. If you decide to apply it to your driveway, know that you won’t have to worry about oil and grease staining it. But for this, you must combine some chemicals with the epoxy coating, such as plasticisers or reactive diluents. Certain additives will help the coating to withstand heat without discolouring as well as prevent it from becoming slick when wet.

It’s Highly Durable

Epoxy resin coatings are not installed in warehouses, car shops, or other industrial facilities just because they are attractive. This material can withstand a great deal of abuse, including dropped tools, fluid leaks, and chemical spills. The sturdiness of this coating explains why they are provided by makers with long warranties. The sealant’s strong bond with the concrete just strengthens it even more.

It Helps Achieve a More Attractive Result

“Strong things don’t look good”, says a proverb, but epoxy coatings don’t fall within this category. From concrete grey to a clear finish, with epoxy coatings, you have a variety of design options. There are even colour choices that closely resemble actual stone, as well as solid colours, speckled or pebbled finishes, and abstract patterns. The fact that it is resistant to scratching and stains, means your concrete surface will look brand new for years to come.

It’s incredibly Low Maintenance

A concrete surface coated with glue can provide the easiest-to-maintain flooring. Since it is permeable, even antifreeze or oil seeping from a car, for example, won’t stain it. To remove these liquids, simply spray a solution of mild detergent and water; no special detergent is required.

What to Consider When Buying Epoxy Glue?

If this is your first time working with this material, you could be discouraged by the fact that it isn’t quite cheap. However, this shouldn’t be an excuse to keep looking for the lowest prices. That is because product variations that are sold at extremely low rates can have a quality that is so poor that it detracts from your enjoyment and makes you less motivated, not to mention that it may entirely sabotage your work.

Health-hazardous solvents that evaporate during the curing process may also be included in some epoxy resins. This could cause the material not to cure entirely. Some inexpensive resins tend to brownish instead of impressing with their crystal-clear transparency. Later, a little sunlight can amplify this unpleasant yellowish tint. That said, aim to invest in an high-quality product.

How to Use Epoxy Glue for Concrete?

Preparing the Surface

Before you apply the resin to your concrete surface, there are a few preparations you must do. The first is to ensure adequate ventilation in the area where you are working. The surface should then be cleaned with warm water and soap and allowed to thoroughly dry.

A utility knife, a mixing tool or applicator, and a disposable mixing surface are all the tools you need. And make sure to use work gloves to protect your hands.

Mixing

Using the mixing tool, blend the resin and the hardener after measuring out the appropriate amounts of each. Make sure to scrape the sides as you mix for about 3 minutes, or until everything is thoroughly combined.

Pouring

Pouring the combined substance only needs to take one crucial factor into account: doing so slowly. You can prevent more bubbles from entering the mixture as you pour by doing it slowly. If there are any bubbles, don’t worry; most of them will pop when the substance cures.

Pour a very thin coating of resin into your mould first, and then use a brush to smooth it out. It will be simpler to spread equally over larger areas this way. Ideally, you should pour the resin right away after mixing.

Cure Time

You must consult the product’s technical data sheet to determine the precise curing time because it will vary depending on the materials used. However, it’s usually advisable to leave the glue in place for as long as you can.

Shelf Life

The glue’s shelf life is 24 months. However, once the containers are opened, this period is drastically decreased, so you should use the material as soon as you can.

Always perform a test pour on any glue that has been sitting in storage for a while to ensure that it is still working as expected. Experts always advise customers to buy only the amount of material they will need for their projects. This will save you from any problems that could arise from using expired products. How to Use Epoxy Glue for Concrete