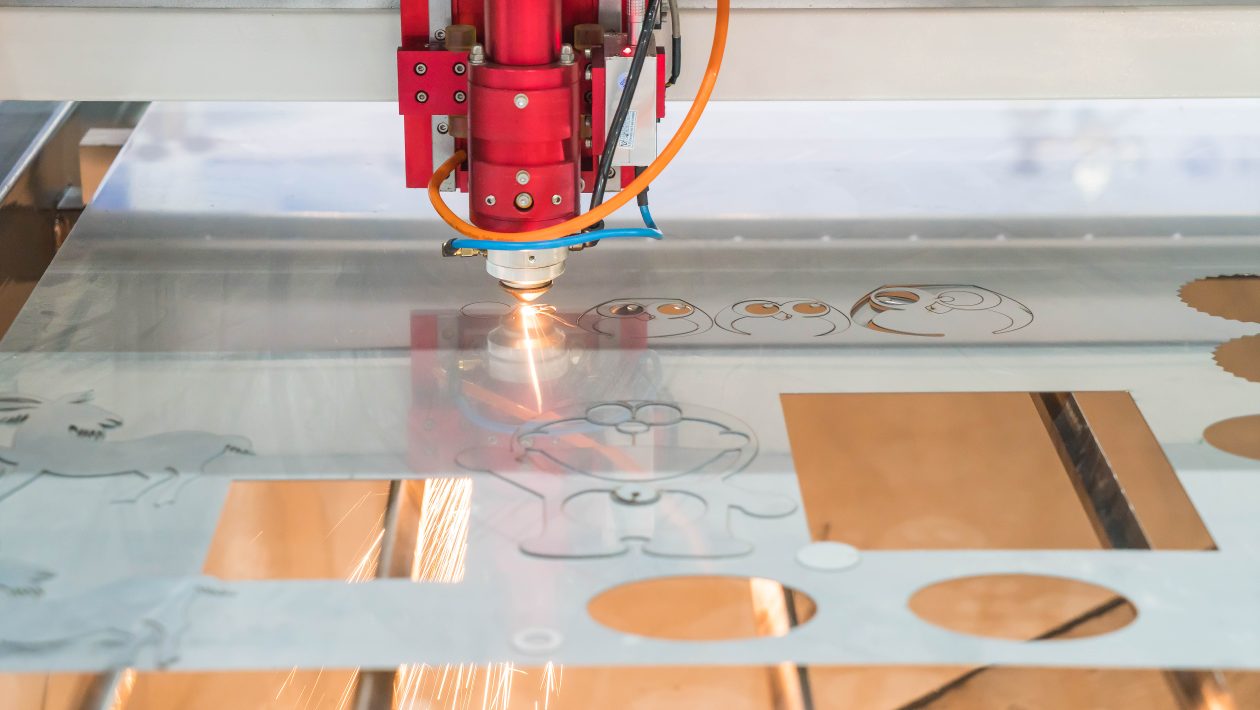

Laser cutting is used in a wide variety of industries. The laser cutting metal process is very precise; it is possible to cut very intricate shapes and small holes on metal plates of different materials. Accuracy is one of the primary advantages of laser cutting when compared to other thermal cutting methods. Accuracy of +/-0.1 mm gives an opportunity to achieve high precision without any after-treatment.

Consider Material Thickness and Type During the Design Process

Before you begin to design your next project, take some time to consider the type of material you need and its thickness. Lasers can cut through thinner material quicker. Knowing the optimal thickness for your part can significantly reduce your laser cutting services costs.

Simplicity is Your Friend

Keeping design details simple is another way you can keep your laser cutting service costs low. Designs in their simplest forms take less time to cut out and therefore cost less. You pay for the time the laser is switched on. So when the technician is cutting, traveling between cuts, or engraving, it all adds up. When planning your designs, cutting small detailed shapes will take longer than larger designs and straight lines take less time compared to circles.

Remember, Laser Cutting Is Just One Piece of Metal Fabrication

There are many companies offering metal fabrication services, many are able to build custom parts and cut tricky designs. However, it is more beneficial to find a company that can handle all of the services that you need in addition to laser cutting, such as powder coating and spot welding. (dayvigo) You may think you’re getting the best price by having different companies perform the different services you need at the lowest prices, but, the more people you work with, the more chances of costly mistakes and delays. It’s worth shopping around for a vendor who offers many services.

It’s Critical to Find the Appropriate Fabrication & Laser Cutting Partner

Successful fabrication projects rely upon absolute precision and 100% accuracy, therefore using companies with professional, experienced, and skilled workers like Arlington Laser Cutting Services, that can perform precision metal laser cutting to produce high-quality accurate products is the key to a successful project.